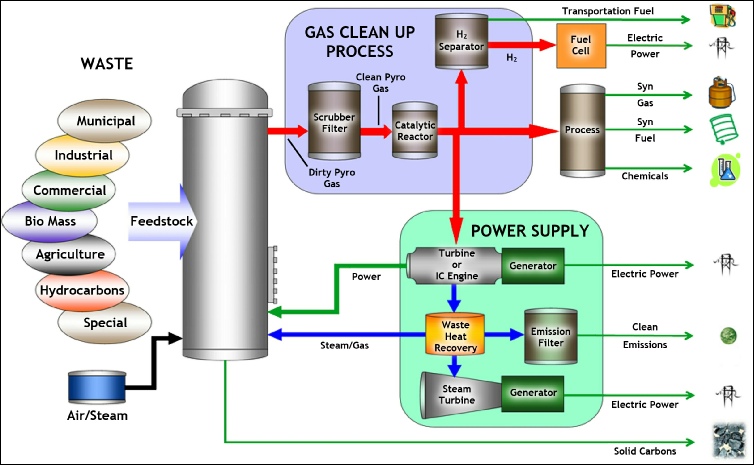

The TCOM process is a controlled application of pyrolysis and gasification under heat and pressure, in which prepared feedstock material placed in sealed reactors is typically converted into gases and solid carbons in approximately 40 – 60 minutes. Gases produced during this process are expelled from the processor and separated into liquid and gaseous fuels and other products, and refined, cleaned, and stored for future use or distribution. Carbons, valuable for manufacture, industrial filtration, and agricultural uses, are released after each processing cycle and stored for future uses.

Plant operation is safe and user-friendly, is not labor-intensive, and does not require sophisticated technical expertise. With the exception of loading and unloading equipment, air compressors, and generators, the system has few moving parts. Core hardware is robust and durable.

In addition, because the conversion process is a naturally exothermic reaction, an installation can be designed so that in continuous processing, only the first processing cycle, which may require no more than 60 – 80 kw to operate, would require external power. Heat generated from the first cycle will initiate subsequent conversion reactions while a portion of the energy or fuels produced from each cycle can be used to power succeeding cycles.